There are many types of tapes, and the total can be divided into conveyor belts and transmission belts. The former is mainly used for transportation of materials in mines, docks and factories; the latter is used for mechanical transmission, and the application is wider, and it is as large as heavy machinery, and it is inseparable from household appliances.

According to different uses and different requirements, the classification of the transmission belt is also becoming more and more refined. It was originally divided into a flat transmission belt (named as a non-working surface in the form of a flat shape, referred to as a flat belt) and a V-belt (a cross-section is wedge-shaped, because the transmission route is two The angular shape, also known as the two-pointed belt in the past, is two major categories. However, with the different transmission requirements, many new varieties are found between them, which play the role of mutual complementarity. The V-ribbed belt is one of them.

(1) Product introduction and structure

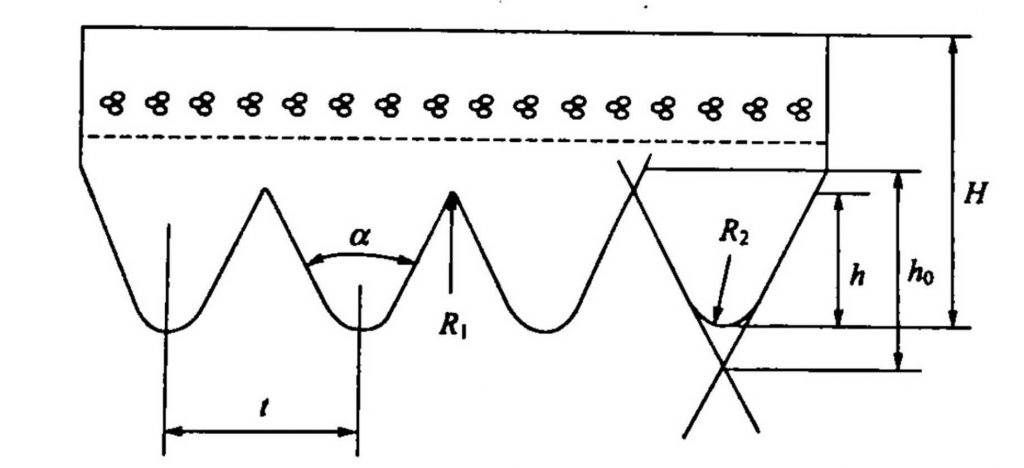

The V-ribbed belt combines the advantages of the flat belt and the V-belt. It is structured with a flat belt as the base and the inner surface is arranged with equidistant longitudinal wedges (the wedge angle is usually 40°). Therefore, the belt combines the length of the two.

The strong layer of the V-ribbed belt is located in the base portion of the flat belt and is not located at the wedge portion like the V-belt. Compared with the flat transmission belt, the V-ribbed belt working surface is composed of a plurality of wedge bodies, thereby increasing the contact surface and frictional force with the pulley, and thus is not easy to slip, thereby improving the transmission efficiency. Compared with the group V belt, there are two merits:

First, the load distribution along the bandwidth is more uniform;

Secondly, the belt body is thinner, and the centrifugal stress and bending stress with respect to the V belt are smaller than that of the ordinary rubber belt. Therefore, a smaller transmission wheel can be configured, and less energy is consumed during operation, and a higher power is obtained. The transmission ratio plays a role in energy saving and consumption reduction. In summary, the V-ribbed belt is a promising transmission tape. Especially in automobiles, it is used in large quantities as an engine drive belt.